Flux Cleaner (Die Form)

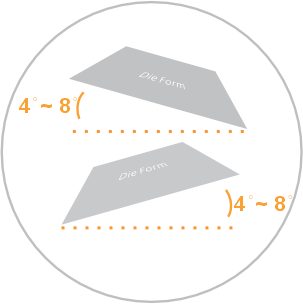

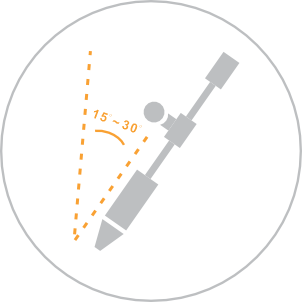

Designed for 2.5D and 3D packaging processes, this system is used for flux cleaning. DIW (deionized water) can be used throughout the entire process. The tilt angles of the spray head (XYZ axes) and the Boat base plate can be adjusted according to process requirements, enabling precise cleaning of gaps to enhance productivity. Fully automated cleaning can also be configured.