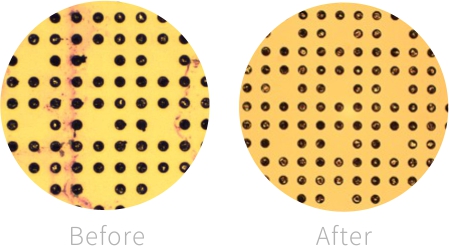

Flux Cleaner (Wafer Form)

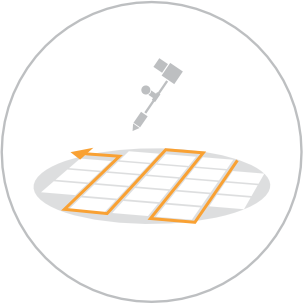

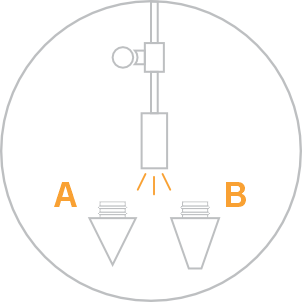

Suitable for advanced packaging wafer cleaning processes. As technology continues to advance, chips are increasing in size while feature gaps are becoming narrower. Semtek utilizes nano-atomizing nozzles combined with a matrix cleaning approach to perform both high-pressure and atomized cleaning, customized for different products and gap dimensions. The system also allows for enhanced localized cleaning performance based on specific process requirements.