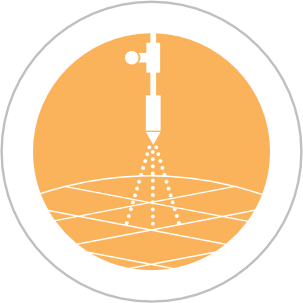

Metal Lift Off

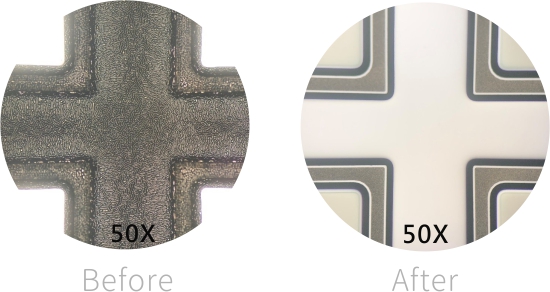

Designed for removing metals and photoresist from wafers. A nano‑scale, high‑pressure atomizing nozzle breaks the cleaning solution into ultra‑fine droplets, enabling rapid reaction with the photoresist. Simply rotate‑rinse to strip away both metal and photoresist; once dissolved, the photoresist becomes floating particles that are spun off the wafer by centrifugal force. The patented nozzle can be tuned for different processes and requirements, allowing intensified rinsing on specific target areas.